150L tank bottom homogenizing tank

Bottom homogenizing tanks are an integral part of the manufacturing industry that helps in the production of high-quality products. Whether it's the pharmaceutical, food, or cosmetic industry, the bottom homogenizing tank plays a vital role in ensuring the final products are uniform, consistent, and of top quality.

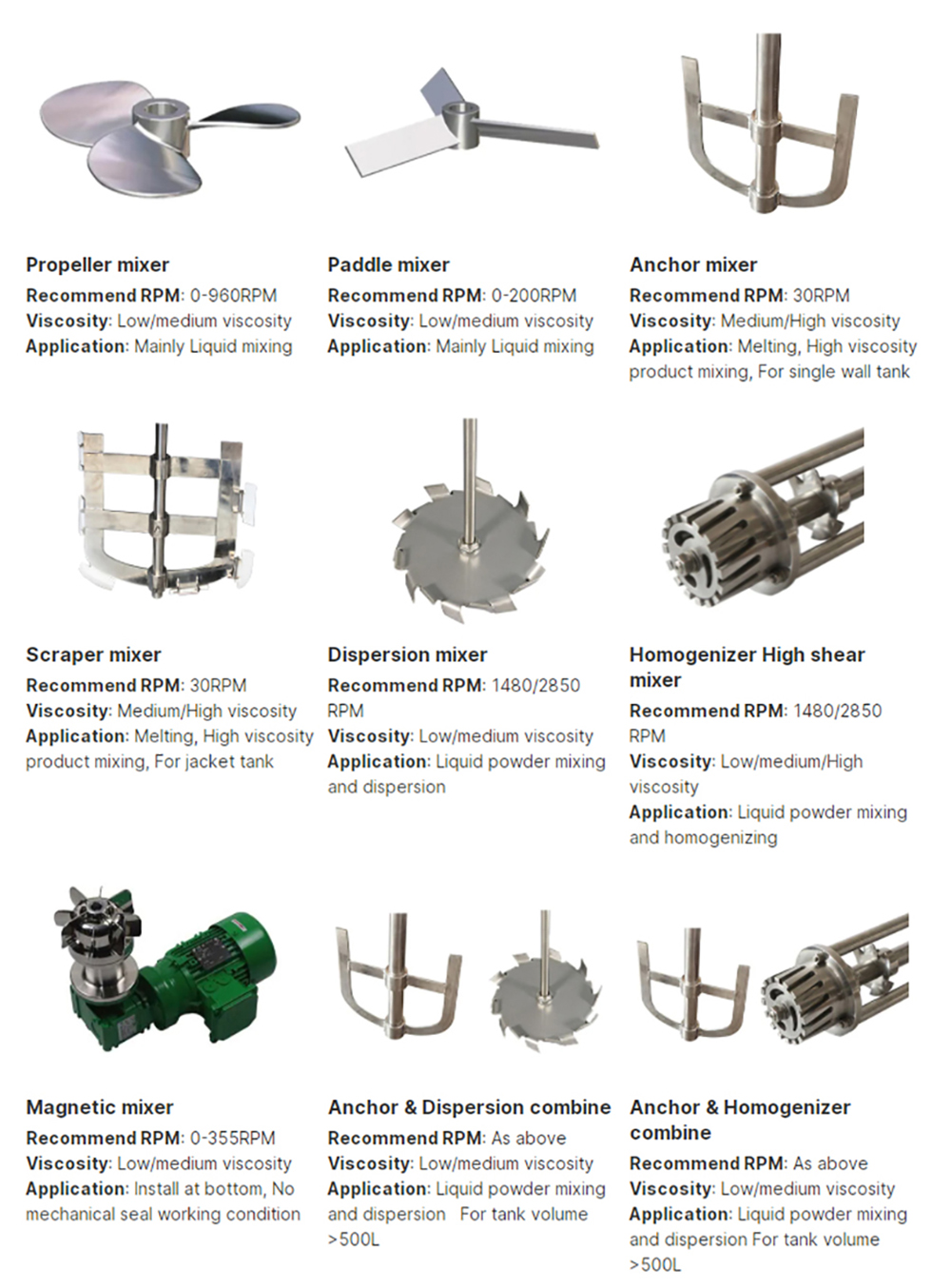

The bottom homogenizing tank operates on the principle of homogenization, which involves the mixing and blending of various components of a product to achieve a uniform blend. The tank is designed with a unique bottom agitator that creates a shearing effect on the product, breaking down any lumps or particles present and ensuring thorough mixing.

One of the significant advantages of using a bottom homogenizing tank is that it prevents product stratification. Stratification, which occurs when heavier materials settle at the bottom of the tank, and lighter materials rise to the top, can lead to inconsistencies in the product. The bottom agitator in the homogenizing tank ensures that the product is thoroughly mixed and that all the components are uniformly distributed, eliminating stratification.

Another advantage of using a bottom homogenizing tank is that it reduces the mixing time required, thereby increasing production efficiency. Traditional mixing methods involve the use of manual labor or slower mixing equipment, which is time-consuming and labor-intensive. However, the bottom homogenizing tank significantly reduces the time required for mixing, thereby increasing productivity and reducing labor costs.

The bottom homogenizing tank also ensures that the final product is of top quality. The thorough mixing and blending of all components ensure that the final product is uniform, consistent, and of high quality. This is particularly important in industries such as pharmaceuticals, where the quality of the final product is crucial to its effectiveness in the treatment of patients.

In conclusion, using a bottom homogenizing tank is essential in ensuring the production of high-quality products in various industries. With its unique bottom agitator, the tank ensures thorough mixing, prevents product stratification, reduces mixing time, and produces a final product of top quality. It is a highly efficient and cost-effective solution that businesses should consider incorporating in their manufacturing processes to produce superior products.