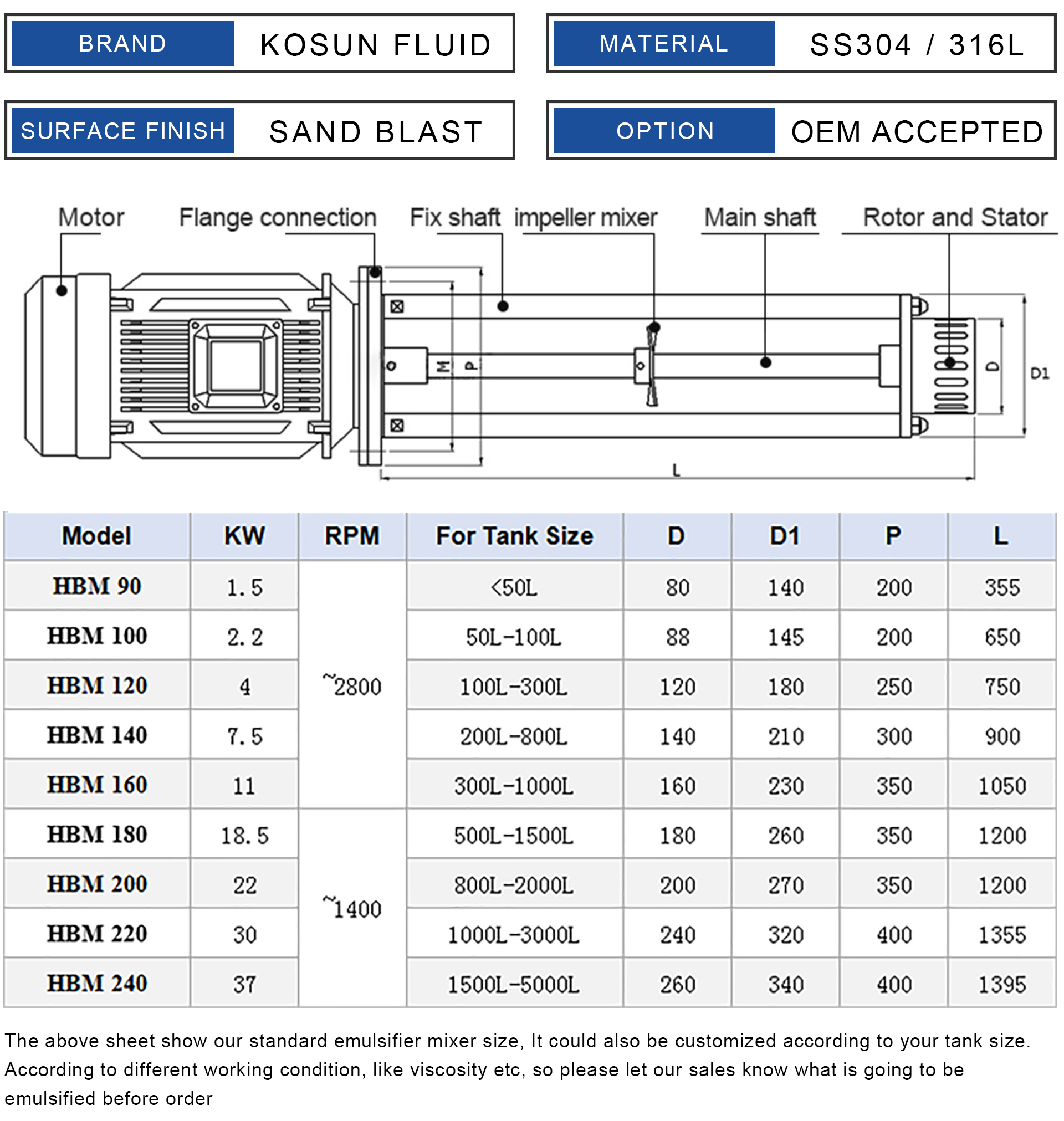

Bottom mounted homogenizer mixer stainless steel

Tank Bottom Homogenizer: An Efficient Solution for Mixing Processes

A tank bottom homogenizer is an innovative blending solution that provides efficient mixing for a wide range of industrial applications. This remarkable technology has changed the way industrial processes are executed and has contributed significantly to many sectors.

Homogenization is an important process for producing uniform mixtures, where various ingredients are blended together to form a consistent end product. Traditionally, mechanical agitators were used for this purpose, but the use of a tank bottom homogenizer has several advantages.

Firstly, this innovative technology ensures better homogenization compared to traditional agitators. The high shear design of the tank bottom homogenizer creates intense turbulence that breaks down particles into smaller sizes, resulting in a uniform mixture. This reduces batch cycle times, ultimately increasing production efficiency.

Secondly, the design of the tank bottom homogenizer reduces the required tank diameters. This reduces the amount of space and material required to house the equipment ultimately lowering production costs.

Thirdly, the homogenizer system is easy to install and operate. Its modular design means that the device can be easily integrated into existing systems, saving time and money.

Finally, tank bottom homogenizers offer excellent versatility, producing consistent blends for a diverse range of products, including juices, dairy products, and pharmaceuticals.

In conclusion, tank bottom homogenizers are changing the industry's approach to mixing processes. This technology provides a cost-efficient, flexible, and efficient method for producing high-quality blended products. The use of a tank bottom homogenizer ensures consistent output and contributes to companies' bottom line, strengthening their competitive edge in the industry.