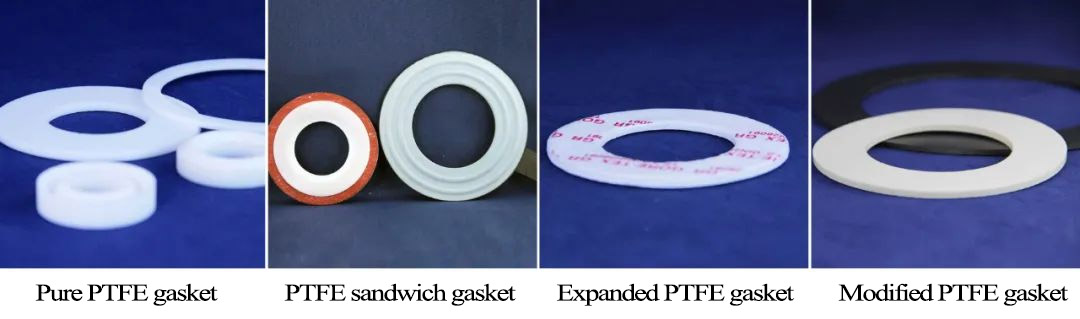

1 Overview and types of PTFE gaskets

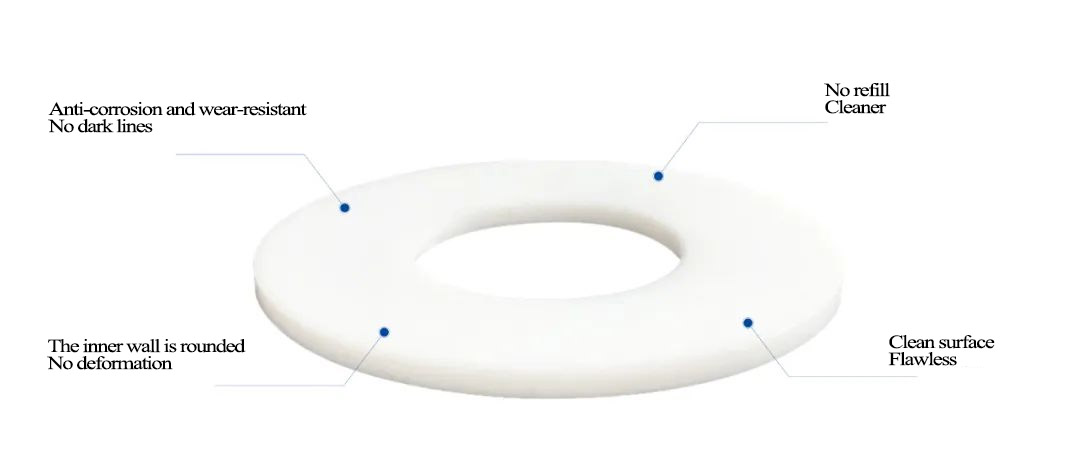

Pure tetrafluoroethylene gasket: PTFE gasket, also known as PTFE gasket or Teflon (Teflon or Teflon) gasket, is a flat gasket formed by mechanical turning or molding of PTFE rods and plates. V-shaped gaskets, piston rings, ball valve gaskets, etc. have good characteristics such as corrosion resistance, aging resistance and non-conductivity.

PTFE has a pH of 0-14 (except molten alkali metals and free fluorine). It can have good mechanical strength between -100℃~100℃. Note: When the temperature is lower than -185℃. PTFE gaskets can become brittle.

Pure PTFE gasket is a clean sealing product that will not contaminate any substances it comes into contact with. It can be widely used in various industries such as food, medicine and strong corrosive occasions.

Modified PTFE gasket (also known as filled PTFE gasket): Modified filled PTFE gasket is a certain amount of filler added to PTFE resin, such as glass fiber, quartz, barium sulfate, graphite, carbon fiber, etc. , After mixing at high speed, it is molded and then sintered at high temperature.

It has excellent compressibility, recovery and sealing. Its unique properties and advanced properties demonstrate sealing and torque retention.

It overcomes the shortcomings of traditional PTFE in terms of cold flow and creep characteristics of the material, and at the same time it can maintain the bolt preload better than traditional PTFE, which not only improves the durability of the seal, but also reduces the maintenance of the flange .

The advantages of filled modified PTFE gasket: low friction coefficient, good compressive strength, improved wear resistance; its use greatly exceeds that of traditional PTFE, which not only improves the environment but also saves costs.

It is widely used in chemical industry, machinery, papermaking, food, low temperature liquid gas, pharmaceutical industry, etc., as well as sealing fields for environments that do not allow pollution.

Expanded PTFE gaskets, also known as expanded PTFE gaskets, expanded PTFE gaskets or soft PTFE gaskets, are developed from 100% PTFE polytetrafluoroethylene through special processing, and have excellent flexibility. It has excellent conformability and forming ability, as well as high tensile strength, creep resistance, high and low temperature resistance, corrosion resistance, cold flow resistance and aging resistance.

It can be stored for a long time without deterioration, non-toxic and non-polluting, and is composed of numerous homogeneous, dense, soft and strong multi-directional fibers, with a unique high-density fiber structure. , Airtight, watertight, and leak-proof performance is good.

In severe corrosive environment and high temperature, it can also maintain an excellent tight state. With a small preload, it can withstand a considerable internal pressure even in a pressure fluctuation environment. It is very suitable for rough or Sealing occasions with uneven wear and fragile glass face flanges and temperature changes.

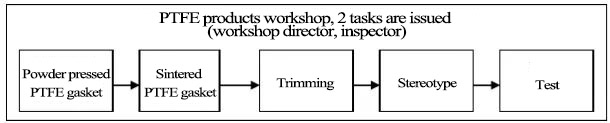

2 The production process of PTFE pad

1) Raw material preparation; ingredients: pure F4 product, raw F4 fine resin, mashed, sieved

2) Mold preparation: wipe clean with alcohol, there is no rust in the mold, no attachments

3) Weighing, according to the formula G=PV (where G is the feeding amount, P is the density of the pre-product (2.18g/cm3) and V is the volume of the product).

4) Feeding: evenly distribute the F4 resin on the entire pressing surface.

5) Preforming (pressing): Calculate the gauge pressure of the press according to the formula, and set the gauge pressure of the press. to suppress

6) Demoulding and trimming: take the semi-finished product out of the mold, and trim its surface to make the surface smooth and the edges neat. Ready to shape.

7) Sintering: slowly put the semi-finished product into the sintering furnace, put it in an appropriate amount, heat it up to about 390 degrees for one hour, and keep it for another hour. Out of the oven, the final shape is completed.

Production cycle of PTFE gasket (referred to as PTFE gasket): at least 3 days for powder pressing; at least 2 days for knife edge molding and cutting, at least 8 days for outsourcing PTFE sheets; at least 3 days for workshop processing; At least 10 days for outsourcing tube or blank.

3 Correct installation of PTFE gasket

1) The PTFE gasket must be placed in the center of the flange, especially on the raised flange;

2) Ensure the flatness and machining accuracy of the sealing surface;

3) The connecting bolts must be tightened evenly and symmetrically;

4) Spring washers must be used to ensure uniform load, and a torque wrench should be used for the high temperature fan when tightening the bolts;

5) Check and recalibrate the torque of the connecting bolts after the system runs for one day;

6) To ensure the service life of the gasket, please do not use liquid or metal matrix anti-sticking agent or lubrication.

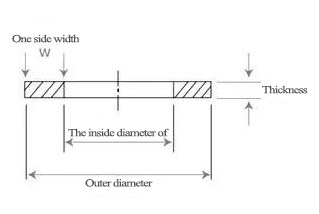

4 Ordering instructions for seals

Flat sealing ring (flat gasket)

The specification consists of inner diameter or outer diameter X thickness (unit: mm)

Note: Unit width = (outer diameter – inner diameter)/2

For example: 10*18*2, inner diameter 10mm, outer diameter 18mm. Thickness 2mm

Post time: Aug-03-2022