Pressure vessels have a wide range of use, a large number and complex working conditions, and the degree of harm caused by accidents varies. The degree of hazard is related to many factors, such as design pressure, design temperature, medium hazard, mechanical properties of materials, use occasions and installation methods. The higher the hazard, the higher the requirements for pressure vessel materials, design, manufacture, inspection, use and management. Therefore, a reasonable classification of pressure vessels is required.

1. Media hazard

The hazard of the medium refers to the toxicity, flammability, corrosiveness, oxidation, etc. of the medium, among which toxicity and flammability are the main factors that affect the classification of pressure vessels.

(1) Toxicity

Toxicity refers to the ability of a chemical poison to cause damage to the body, and is used to express the relationship between the dose of the poison and the toxic response. The size of toxicity is generally expressed in terms of the dose required for a chemical substance to cause a certain toxic reaction in experimental animals. Gaseous poison, expressed as the concentration of the substance in the air. The lower the concentration of the required dose, the greater the toxicity.

When designing pressure vessels, according to the maximum allowable concentration of chemical media, China classifies chemical media as extremely hazardous (Ⅰ

There are four levels: high hazard (level Ⅱ), moderate hazard (level Ⅲ), and mild hazard (level Ⅳ). The so-called maximum allowable concentration refers to the highest concentration that is considered not to be harmful to the human body from the medical level, expressed in milligrams of toxic substances per cubic meter of air, and the unit is mg/m3. The general classification criteria are:

Extremely hazardous (Class I) maximum allowable mass concentration <0.1mg/m3;

Highly hazardous (Class II) maximum allowable mass concentration 0.1~<1.0mg/m3;

Moderate hazard (grade III) maximum allowable mass concentration 1.0~<10mg/m3;

Mild hazard (grade IV) The maximum allowable mass concentration is ≥10mg/m3.

The higher the toxicity of the medium, the more serious the harm caused by the explosion or leakage of the pressure vessel, and the higher the requirements for material selection, manufacture, inspection and management. For example, Q235-B steel plates shall not be used to manufacture pressure vessels with extremely or highly hazardous media; when manufacturing containers containing extremely or highly hazardous media, carbon steel and low-alloy steel plates shall be subjected to ultrasonic testing one by one, and the overall Post-weld heat treatment must be carried out, and the Class A and B welded joints on the container should also be subjected to 100% ray or ultrasonic testing, and the air tightness test must be carried out after the hydraulic test is qualified.

The requirements for the manufacture of containers with moderate or mild toxicity are much lower. The degree of toxicity has a great influence on the selection of flanges, which is mainly reflected in the nominal pressure level of the flange. If the internal medium is moderately toxic, the nominal pressure of the selected pipe flange should not be less than 1.0MPa; the internal medium is high or Extreme toxicity hazards, the nominal pressure of the selected pipe flange should not be less than 1.6MPa, and the butt welding flange with neck should also be used as much as possible.

(2) Flammability

The mixture of combustible gas or vapor and air is not combustible or explosive in any proportion, but has a strict quantitative proportion and changes due to changes in conditions. The research shows that when the content of combustible gas in the mixture meets the conditions of complete combustion, the combustion reaction is the most violent. If its content decreases or increases, the flame burning speed will decrease, and when the concentration is lower or higher than a certain limit value, it will no longer burn and explode. The concentration range at which a mixture of combustible gas or vapor and air will explode immediately upon encountering a fire source or a certain detonation energy is called the explosion concentration limit, the lowest concentration at the time of explosion is called the lower explosion limit, and the highest concentration is called the upper explosion limit.

The explosion limit is generally expressed by the volume fraction of flammable gas or vapor in the mixture. The medium with the lower explosion limit less than 10%, or the difference between the upper explosion limit and the lower limit is greater than or equal to 20%, generally referred to as flammable media, such as methane, ethane, ethylene, hydrogen, propane, butane, etc. Flammable media include flammable gases, liquids and solids. The flammable medium contained in the pressure vessel mainly refers to flammable gas and liquefied gas.

Flammable media put forward higher requirements on the selection, design, manufacture and management of pressure vessels. All welds (including fillet welds) of flammable medium pressure vessels shall adopt a full penetration structure, etc.

2. Classification of pressure vessels

Different countries in the world have different classification methods for pressure vessels. This section focuses on the classification methods in China’s “Stationary Pressure Vessel Safety Technical Supervision Regulations”.

(1) Classification by pressure level

According to the type of pressure, pressure vessels can be divided into internal pressure vessels and external pressure vessels. The internal pressure vessel can be divided into four pressure levels according to the design pressure (p), which are divided as follows:

Low pressure (code L) container 0.1MPa≤p<1.6MPa;

Medium pressure (code M) container 1.6MPa≤p<10.0MPa;

High pressure (code H) container 10MPa≤p<100MPa;

Ultra-high pressure (code U) container p≥100MPa.

In the external pressure container, when the internal pressure of the container is less than an absolute atmospheric pressure (about 0.1MPa), it is also called a vacuum container.

(2) Classification according to the role of containers in production

According to the function of the pressure vessel in the production process, it can be divided into four types: reaction pressure vessel, heat exchange pressure vessel, separation pressure vessel and storage pressure vessel. The specific division is as follows.

① Reaction pressure vessel (code R) is mainly used to complete the physical and chemical reaction of the medium, such as reactor, reaction kettle, polymerization kettle, autoclave, synthesis tower, autoclave, gas generator, etc.

② Heat exchange pressure vessel (code E) is mainly used to complete the medium heat exchange pressure vessel. Such as shell and tube waste heat boilers, heat exchangers, coolers, condensers, evaporators, heaters, etc.

③ Separation pressure vessel (code S) is mainly used to complete the pressure balance buffer of medium fluid and gas purification and separation. Such as separators, filters, oil collectors, buffers, drying towers, etc.

④ Storage pressure vessel (code C, in which spherical tank code B) is mainly used for storing and containing gas, liquid, liquid

Pressure vessels for gas and other media. Such as liquid ammonia storage tanks, liquefied petroleum gas storage tanks, etc.

In a pressure vessel, if there are two or more process principles at the same time, the varieties should be divided according to the main role in the process.

(3) Classification by installation method

According to the installation method, it can be divided into fixed pressure vessels and mobile pressure vessels.

① Fixed pressure vessel refers to the pressure vessel with fixed installation and use site, and relatively fixed process conditions and operators. Such as horizontal storage tanks, spherical tanks, towers, reactors, etc. in the production workshop.

② Mobile pressure vessel refers to the transport equipment composed of tanks or large-volume gas cylinders and traveling gear or frames that are permanently connected, including railway tank cars, automobile tank cars, long-pipe trailers, tank containers, and tube-bundle containers. Mobile pressure vessels need to consider inertial force and liquid sloshing during transportation, so they have special requirements in terms of structure, use and safety.

A pressure vessel that has the function of loading and unloading medium, is only used in the device or field, and does not participate in railway, road or water transportation is not a mobile pressure vessel.

(4) Classification by safety technology management

The several classification methods mentioned above only consider a certain design parameter or use condition of the pressure vessel, and cannot comprehensively reflect the overall hazard level faced by the pressure vessel. For example, a pressure vessel that stores flammable or moderately toxic or more hazardous media is much more hazardous than a pressure vessel of the same geometric size that stores mildly toxic or non-flammable media.

The hazard of the pressure vessel is also related to the product of its design pressure p and the full volume V. The larger the pV value, the greater the explosion energy and the greater the hazard when the vessel ruptures. The design, manufacture, inspection, use and management of the vessel higher requirements.

For this reason, considering factors such as design pressure, volume, medium hazard, the role of the vessel in production, material strength, vessel structure and other factors, the “Pressure Vessel Safety Technical Supervision Regulations” divides pressure vessels within the applicable scope into three categories. That is, the first type of pressure vessel, the second type of pressure vessel and the third type of pressure vessel.

In the process of use, it is found that the focus of this classification method is not prominent. For multi-functional pressure vessels, it is difficult to define which function plays a major role in production, which easily leads to inconsistent opinions when classifying. At the same time, with the advancement of material science and manufacturing technology, material strength, container structure, etc. are no longer the main factors affecting the risk level of containers.

In view of the above problems, in order to make the classification simple and unique, China’s “Stationary Pressure Vessel Safety Technology Supervision Regulations” classifies pressure vessels according to three factors, such as medium, design pressure and volume, and classifies pressure vessels within the applicable scope into Category I. For pressure vessels, Class II pressure vessels and Class III pressure vessels, the classification methods are now introduced.

① Grouping of medium The medium of the pressure vessel is gas, liquefied gas, and liquid whose maximum working temperature is higher than or equal to its standard boiling point, and is divided into two groups according to the degree of toxicity and explosion risk.

ⅰ. The first group of media: chemical media, explosive media, and liquefied gases whose toxicity hazard degree is extremely hazardous and highly hazardous.

ii. The second set of media: media other than the first set of media.

The toxicity hazard degree and explosion hazard degree of the medium are determined according to the two standards of GBZ230 “Classification of the Hazard Degree of Occupational Exposure to Poisons” and HG20660 “Classification of the Toxicity Hazard and Explosion Hazard Degree of Chemical Medium in Pressure Vessels”. When the two are inconsistent, the one with the highest degree of hazard (dangerous) shall prevail.

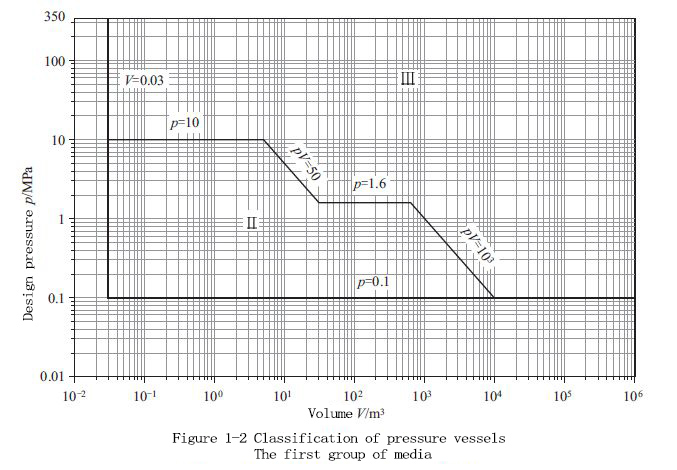

② Classification of pressure vessels The classification of pressure vessels should first select the corresponding classification diagram according to the characteristics of the medium, and then

Measure the pressure p (unit MPa) and volume V (unit m3), mark the coordinate points, and determine the container category.

i. For the first group of media, the classification of pressure vessels is shown in Figure 1-2.

When the coordinate point is located on the classification line of Figure 1-2 or Figure 1-3, it is classified according to the higher category; the volume is less than 25L or the inner diameter (for non-circular sections, it refers to the width, height or diagonal line, such as the rectangle is Small-volume pressure vessels with a diagonal line and an ellipse as the major axis) less than 150 mm are classified as Class I pressure vessels; the media not specified in the two standards GBZ230 and HG20660 shall be comprehensively considered according to their chemical properties, degree of hazard and content , The medium group is determined by the pressure vessel design unit.

Due to the differences in economic policies, technical policies, industrial bases and management systems of various countries, the classification methods of pressure vessels are also different from each other. When designing pressure vessels using international standards or advanced foreign standards, corresponding classification methods should be adopted.

For example, the EU 97/23/EC “Pressure Equipment Directive” comprehensively determines the hazards of pressure equipment according to factors such as allowable working pressure, vapor pressure at the maximum allowable working temperature, medium hazard, geometric volume or nominal size, and use. The pressure-bearing equipment is divided into four categories: I, II, III, and IV, and the corresponding material, design, manufacture and inspection requirements are given.

Another example is Japan’s JISB8270 “Pressure Vessel (Basic Standard)” promulgated in 1993, which divides pressure vessels into three grades according to the design pressure and the hazard of the medium: the third type of pressure vessel has the lowest grade, and the scope of application is that the design temperature is not lower than 0 ℃, the design pressure is less than 1MPa; the design pressure of the second type of pressure vessel is less than 30MPa; and the design pressure of the first type of pressure vessel should generally be less than 100MPa. However, if there are special requirements for materials, manufacturing, inspection, etc., pressure vessels with a design pressure higher than 100MPa can also be classified into the first category of vessels.

Post time: Sep-19-2022