Kuwotcherera khalidwe la kuwotcherera msoko wa zitsulo zosapanga dzimbiri kuthamanga madzi thanki mwachindunji zimakhudza chitetezo chotengera chotengera.Pali njira zambiri zowotcherera, kuwotcherera kwa argon arc ndi imodzi mwa njira zabwino zowotcherera, koma kukula kwake kukakhala kokulirapo kuposa 800mm ndipo voliyumu ndi yayikulu, chitetezo chamkati cha argon chimabweretsa zovuta ndikuwonjezera mtengo wopanga.Njira yowotcherera ya arc-argon arc imagwiritsidwa ntchito kwambiri pakuwotcherera kwa msoko wozungulira ndi msoko wotalika wa chidebe, chomwe chimathandizira kwambiri kuwotcherera kwabwino komanso kuwotcherera bwino ndikuchepetsa mtengo wopanga.

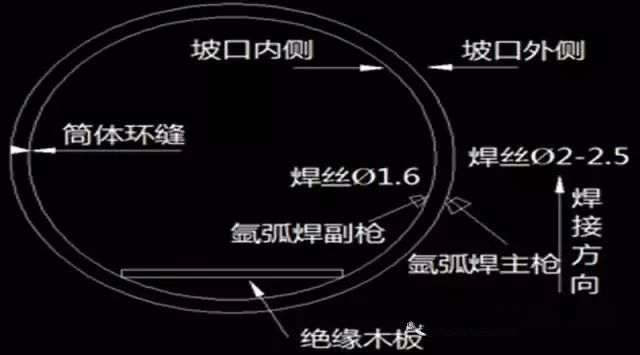

Mgolowu umatengera njira yowotcherera ya mbali ziwiri ya arc bottoming ya argon arc, ndipo chogwiriracho chimapangidwa kukhala mbali imodzi yokhala ngati V.Pamalo ofukula, ma welder awiri ndi magwero awiri odziyimira pawokha amagwiritsidwa ntchito kulumikiza mbali zamkati ndi zakunja za workpiece ndi dziwe losungunuka.kuwotcherera.Pambuyo kuwotcherera pansi, kudzaza ndi kuwotcherera kwa chivundikiro kumatsirizidwa ndi arc imodzi.Imathetsa njira yapitayi yodzaza argon kumbali yakumbuyo ndikuchepetsa kuyeretsa mizu kumbuyo;ili ndi weldability wabwino ndipo imatha kuwongolera bwino kutalika kwa reverse side weld;chifukwa arc iwiri imawonjezera mphamvu yotsitsimutsa ya dziwe losungunuka ndi madzi amadzimadzi a dziwe losungunuka, likhoza kupanga dziwe losungunuka kwathunthu Fusion imachepetsa zolakwika monga slag inclusions, pores, ndi kulowa kosakwanira;ili ndi mawonekedwe a kulowetsamo kutentha pang'ono, kuwotcherera kwazing'ono, kuchepetsa kupanikizika kwa mgwirizano, komanso kuwonjezereka kwambiri.

Zofunikira pamisonkhano

1.1 Gwiritsani ntchito nsanja yapadera panthawi yosonkhanitsa kuti muzipatula kuzinthu zina zazitsulo monga carbon steel;pewani kukwapula komwe kumachitika chifukwa cha kugunda paulendo;gulaye ndi zida zapadera, monga malamba a nayiloni, ayenera kugwiritsidwa ntchito pokweza, ndipo zingwe zama waya zachitsulo ndizoletsedwa kuti zisakanda pamwamba pazitsulo.

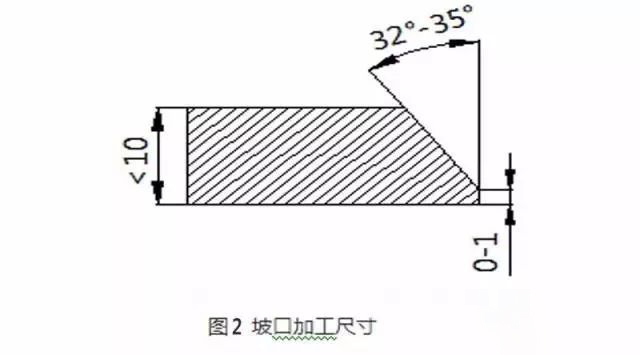

1.2 Sankhani mbale zoyenerera motsatizana ndi zofunikira za mapangidwe a zojambulazo, dziwani kukula kwenikweni kwa chinthu chilichonse, gwiritsani ntchito kudula kwa plasma kapena machining kuti mudulire zinthuzo, ndipo grooves iyenera kukonzedwa ndi makina kapena njira zopera.Pokonza, mutu umagwedezeka ndi chopukusira, ndipo miyeso yeniyeni ikuwonetsedwa mu Chithunzi 2.

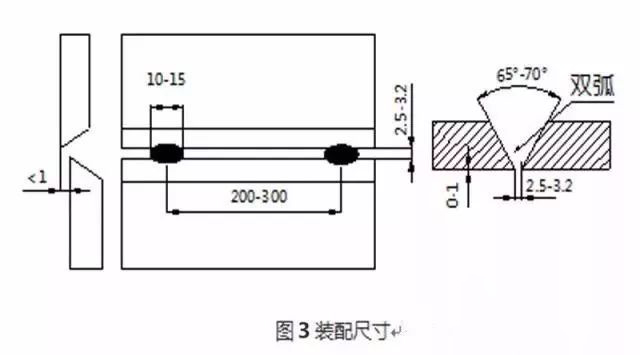

Pambuyo pomaliza, kugudubuza kwa waya katatu kumagwiritsidwa ntchito pokonza arc.Kukula kwa msonkhano kukuwonetsedwa mu Chithunzi 3. Yeretsani 10 ~ 15mm mbali zonse za poyambira, kusiyana kwa msonkhano ndi 2.5 ~ 3.2mm, kuchotsera kwa mbale sikuchepera 10% ya makulidwe a khoma, ndipo osapitirira 1mm. , pogwiritsa ntchito kuwotcherera argon arc, kutalika 10 ~ 15mm, makulidwe 3 ~ 4mm.Kuyambika kwa arc ndi kuchotsedwa kwa arc kuyenera kuchitika pankhope ya groove.Mukatha kusonkhanitsa, gwiritsani ntchito chopukutira kupukuta kutsogolo ndi kumbuyo kwa zolumikizira zolumikizira kuti muwone kunyezimira.

1.3 Pamsonkhano, pewani kukakamiza kuti muchepetse kupsinjika kwapakati pazigawo.Yesetsani kupewa zinthu zina zomwe zingawononge kapena kukanda pamwamba pa bolodi.

Ndizoletsedwa kugunda ma arcs mwachisawawa kapena kuwotcherera mwachisawawa ndikuyika zida zosakhalitsa pamwamba pa silinda.Malo a mbali zonse za weld ayenera kupewa kugwiritsa ntchito nyundo kukonza izo.

Njira yowotcherera

2.1 Kukonzekera pamaso kuwotcherera

Tsukani dzimbiri wosanjikiza, chinyezi, mafuta, fumbi, etc. 10-15mm mbali zonse za poyambira.

2.2 Kusankha zinthu zowotcherera zomwe zimagwiritsidwa ntchito nthawi zambiri (onani Gulu 1)

| Chitsulo choyambira | Wowotcherera waya |

| Mtengo wa 304 | Mtengo wa ER308 |

| Mtengo wa 304L | Mtengo wa ER308L |

| Mtengo wa 316 | Mtengo wa ER316 |

| Mtengo wa 316L | Mtengo wa ER316L |

| Mtengo wa 321 | Mtengo wa ER321 |

Zowotcherera (onani Gulu 2)

| Kunenepa kwachitsulo choyambira (mm) | Waya awiri (mm) | Kuwotcherera pamwamba | Mtundu wamakono ndi polarity | Welding panopa (A) | Kutuluka kwa gasi (L/mphindi) |

| 4-10 | Φ1.6 | Non-groove | Kulumikizana kwabwino kwa DC | 20-50 | 6-10 |

| Φ2-2.5 | nkhope ya bevel | Kulumikizana kwabwino kwa DC | 70-110 | 8-10 |

2.3 Njira zopewera kuwotcherera

Sankhani zoyenera kuwotcherera zakuthupi monga mbale, ntchito Φ1.6mm kuwotcherera waya mkati kuwotcherera, kuwotcherera panopa 20~50A, kunja kusankha Φ2 ~ 2.5mm kuwotcherera waya malinga makulidwe a mbale, kuwotcherera panopa 70~110A, ndi ntchito otsika panopa kudya kuwotcherera kwa bottoming.Kudzaza zigawo ndi capping ayenera kusankha njira kuwotcherera monga argon arc kuwotcherera, electrode arc kuwotcherera, ndi CO2 mpweya wotetezedwa kuwotcherera malinga ndi mikhalidwe.Pamene makulidwe mbale ndi zosakwana 10mm, yesetsani ntchito kumizidwa arc basi kuwotcherera.

2.4 Kuyang'anira kuwotcherera

Pambuyo pa maola 48 akuwotcherera, filimu ndi kuyesa kosawononga kwa msoko wowotcherera kumachitika.Izi zimagwiritsa ntchito kuwotcherera kwa arc arc arc kwa kuyika pansi, kuwotcherera kwa argon arc kuti mudzaze chophimba pamwamba, kujambula kujambula kwa msoko ndi kuyesa kosawononga mtundu zonse ndizoyenera, ndipo mayeso opindika, kuyesa kwamphamvu kwamphamvu ndi kuyesa kwa dzimbiri kwa intergranular zizindikiro zotchulidwa.

2.5 Chithandizo cha post-weld

Pambuyo poyesa kosawononga ndi kuyesa mphamvu, pickling ndi passivation mankhwala amachitidwa pa weld ndi pafupi msoko m'dera.

Njira yowotcherera yokhala ndi mbali ziwiri ya arc arc yachitsulo chosapanga dzimbiri ndi imodzi mwa njira zabwino zowotcherera.Monga njira yabwino kwambiri, yopulumutsira mphamvu, yapamwamba komanso yowotcherera yachuma, kuwotcherera kwa arc awiri kumakhala ndi chiyembekezo chabwino chogwiritsa ntchito kupanga kwenikweni.

Nthawi yotumiza: Jun-13-2022