Iyo welding mhando yewelding seam yestainless simbi yekumanikidza mvura tangi inokanganisa zvakananga kuchengetedzwa kwemudziyo wekumanikidza.Kune nzira dzakawanda dzewelding, argon arc welding ndiyo imwe yedzakanakisa nzira dzewelding, asi kana iyo dhayamita yakakura kupfuura 800mm uye vhoriyamu yakakura, iyo yemukati argon yekuzadza dziviriro inounza mamwe matambudziko uye inowedzera mutengo wekugadzira.Iyo kaviri-arc argon arc welding process inonyanya kushandiswa kukwenenzvera kweinotenderera musono uye longitudinal seam yemudziyo, iyo inovandudza zvakanyanya kunaka kwewelding nekushanda kwewelding uye inoderedza mutengo wekugadzira.

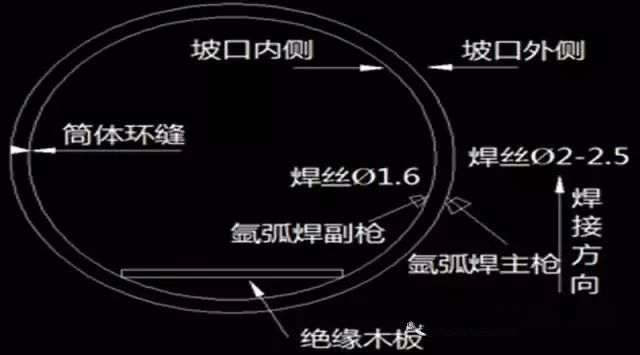

Iyo dhiramu inotora yakapetwa kaviri-arc bottoming welding process yeargon arc welding, uye workpiece inogadzirwa kuita rimwe-sided V-shaped groove.Munzvimbo yakatwasuka, mawelder maviri uye maviri akazvimiririra masimba emagetsi anoshandiswa kubatanidza mukati nekunze mativi eworkpiece nedziva rakanyungudutswa.welding.Mushure mekucheka kwepasi, kuzadza uye kuvhara kwekuvhara kunopedzwa nearc imwe chete.Inobvisa maitiro ekare ekuzadza argon kune reverse side uye inoderedza nzira yekuchenesa midzi kudivi rekuseri;ine weldability yakanaka uye inogona kunyatso kudzora kureba kwereverse side weld;nokuti arc kaviri inowedzera simba rinokurudzira redziva rakanyungudutswa uye kunyunguduka kwedziva rakanyungudutswa, rinogona kuita kuti dziva rakanyungudutswa zvizere Fusion inoderedza kuremara kwakadai se slag inclusions, pores, uye kupinda kusina kukwana;ine maitiro ekupisa kudiki kupinza, kudiki welding deformation, kuderedzwa kwekubatana kushushikana, uye zvakanyanya kuwedzera kupinda.

Gungano rinodiwa

1.1 Shandisa puratifomu yakakosha panguva yekuungana kuti uitsaure kubva kune zvimwe zvinhu zvesimbi senge kabhoni simbi;dzivisa kukwenya kunokonzerwa nekudhumhana panguva yekufambisa;zvipfuramabwe zvakakosha uye zvigadziriso, zvakaita semabhandi enaironi, zvinofanirwa kushandiswa kusimudza, uye tambo dzesimbi dzakanyanya kurambidzwa kudzivirira kukwenya pamusoro pesimbi.

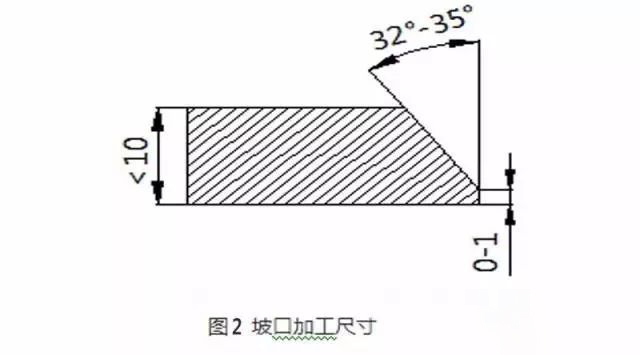

1.2 Sarudza mahwendefa akakodzera zvakanyatsoenderana nezvinodiwa zvekugadzirwa kwemifananidzo, sarudza saizi chaiyo yechinhu chimwe nechimwe, shandisa plasma yekucheka kana machining kucheka zvinhu, uye grooves inofanira kugadzirirwa nekugadzira kana kugaya nzira.Kuti ugadzirise, musoro wakanyungudutswa neguyo, uye hukuru hwacho hunoratidzwa muMufananidzo 2.

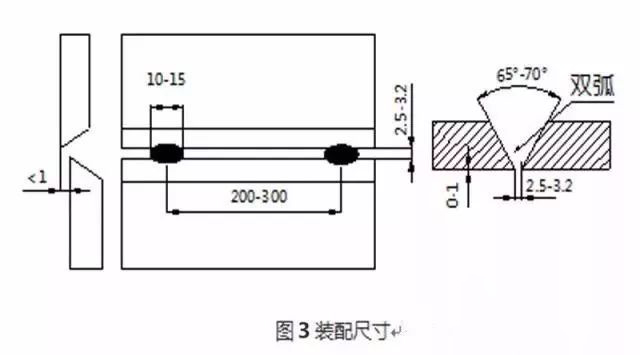

Mushure mekugadzirisa kwapera, matatu-waya rolling inoshandiswa pakugadzirisa arc.Saizi yegungano inoratidzwa muMufananidzo 3. Chenesa 10 ~ 15mm pamativi ese egorofu, gaka regungano iri 2.5 ~ 3.2mm, iyo dhizaini yeplate iri pasi pe10% yehukobvu hwemadziro, uye kwete kupfuura 1mm. , uchishandisa argon arc welding, kureba 10 ~15mm, ukobvu 3~4mm.Iyo arc initiation uye arc kumisa kunofanirwa kuitwa pachiso chegroove.Mushure mekusangana, shandisa polisher kukwenenzvera kumberi nekumashure kwemajoini anotengeswa kuti uone kupenya.

1.3 Panguva yegungano, dzivisa kumanikidzwa kuungana kuti uderedze kushushikana kwemukati kwezvikamu.Edza kudzivirira zvimwe zvinhu zvinosvibisa kana kukwenya pamusoro pebhodhi.

Izvo zvinorambidzwa kurova zvisina tsarukano ma arcs kana kusarongeka weld uye nekuisa zvinhu zvenguva pfupi pamusoro pehumburumbira.Nzvimbo dziri kumativi maviri e weld dzinofanira kudzivisa kushandisa sando kuigadzirisa.

Welding process

2.1 Kugadzirira usati welding

Chenesa marara, unyoro, mafuta, guruva, nezvimwewo 10-15mm kumativi ose egorofu.

2.2 Kusarudzwa kwezvinhu zvinowanzo shandiswa welding (ona Tafura 1)

| Nheyo yesimbi | Welding waya |

| SUS 304 | ER308 |

| SUS 304L | ER 308L |

| SUS 316 | ER316 |

| SUS 316L | ER 316L |

| SUS 321 | ER 321 |

Welding parameters (ona Tafura 2)

| Base metal ukobvu (mm) | Waya dhayamita (mm) | Welding pamusoro | Ikozvino mhando uye polarity | Welding ikozvino (A) | Kuyerera kwegasi (L/min) |

| 4-10 | Φ1.6 | Non-groove | DC positive connection | 20~50 | 6~10 |

| Φ2~2.5 | Bevel face | DC positive connection | 70~110 | 8~10 |

2.3 Welding precautions

Sarudza iyo yakakodzera welding material maererano nendiro, shandisa Φ1.6mm welding wire mukati meweld, welding current 20~50A, kunze sarudza Φ2~2.5mm welding wire zvichienderana nekukora kweplate, welding current 70~110A, uye shandisa low current fast welding for bottoming.Kuzadza uye kuvharira maseru kunofanirwa kusarudza nzira dzewelding senge argon arc welding, electrode arc welding, uye CO2 gasi rakadzivirirwa welding zvinoenderana nemamiriro chaiwo.Kana hukobvu hwendiro huri pasi pe10mm, edza kusashandisa yakanyura arc otomatiki welding.

2.4 Welding kuongorora

Mushure memaawa makumi mana nemasere ekushongedza, firimu uye ruvara rusingaparadze kuedza kweiyo welding seam inoitwa.Iyi nzira inotora kaviri-arc argon arc welding yekudzikisa pasi, argon arc welding yekuzadza chivharo chepamusoro, welding seam filming uye isingaparadze kuyedzwa kweruvara zvese zvinokodzera, uye bvunzo yekukotama, tensile simba bvunzo uye intergranular corrosion bvunzo zvese zvinosangana. zviratidzo zvakatarwa.

2.5 Post-weld kurapwa

Mushure mekuedza kusingaparadzi uye kuedza kwesimba, pickling uye passivation kurapwa kunoitwa pane weld uye pedyo seam nzvimbo.

Maitiro ekudzika maviri-mativi maviri-arc argon arc welding yesimbi isina tsvina ndiyo imwe yedzakakodzera nzira dzewelding.Seyepamusoro-inoshanda, inochengetedza simba, yepamusoro-mhando uye yehupfumi welding process, kaviri-arc welding ine yakanaka yekushandisa tarisiro mukugadzirwa chaiko.

Nguva yekutumira: Jun-13-2022