stainless steel 50L 500L 1000L 5000L mixing tank

Stainless steel mixing tank is an essential piece of equipment in many industries, including pharmaceutical, food, chemical, and cosmetic. These tanks are known for their durability, resistance to corrosion, and sanitary properties, making them a popular choice for manufacturers. With its many benefits, stainless steel mixing tanks have become an integral part of many production and manufacturing processes.

One of the main advantages of stainless steel mixing tanks is their resistance to corrosion. These tanks are designed to withstand harsh chemicals and acidic substances without rusting or deteriorating, making them suitable for use in corrosive environments. Furthermore, stainless steel has a non-porous surface, which prevents the buildup of bacteria and other microorganisms, making it easy to clean and maintain.

Stainless steel mixing tanks are also known for their durability and strength. They can handle heavy loads and high pressure, making them an excellent choice for applications that require precise mixing and blending. Stainless steel is also resistant to extreme temperatures, which means that it can withstand high heat and cold without affecting its structural integrity.

Another benefit of stainless steel mixing tanks is their hygienic properties. These tanks can be cleaned and sanitized easily, making them ideal for use in the food and pharmaceutical industries. With their non-reactive properties, stainless steel mixing tanks ensure that product quality is not compromised, and there is no risk of contamination.

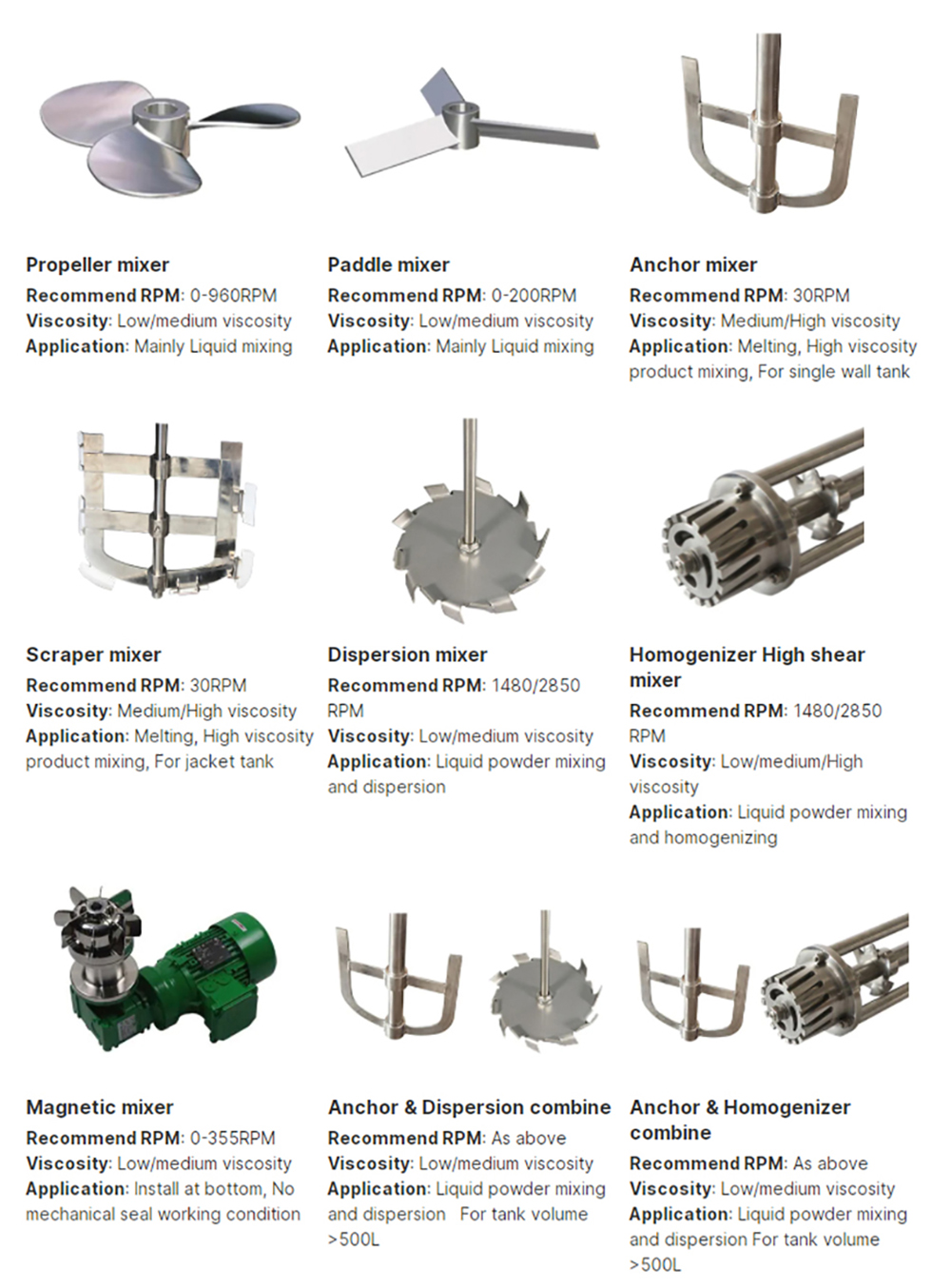

In conclusion, stainless steel mixing tanks are a valuable investment for any manufacturer looking to optimize their production processes. With their durability, strength, and resistance to corrosion, these tanks are the ideal choice for applications that require precise mixing and blending. The hygienic properties of stainless steel make it an excellent choice for the food and pharmaceutical industries. There are many types of stainless steel mixing tanks available on the market, each with distinct features and capabilities, making it essential to choose the right one for your particular application.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur