Stainless steel agitated Pharmaceutical Reaction Tank

The reaction tank is a comprehensive reaction vessel. The structure, function and configuration accessories of the reaction vessel are designed according to the reaction conditions. From the beginning of the feed reaction discharge, the preset reaction steps can be completed with a high degree of automation, and the temperature, pressure, mechanical control (stirring, blast, etc.), reactants products during the reaction process Important parameters such as concentration are strictly regulated.

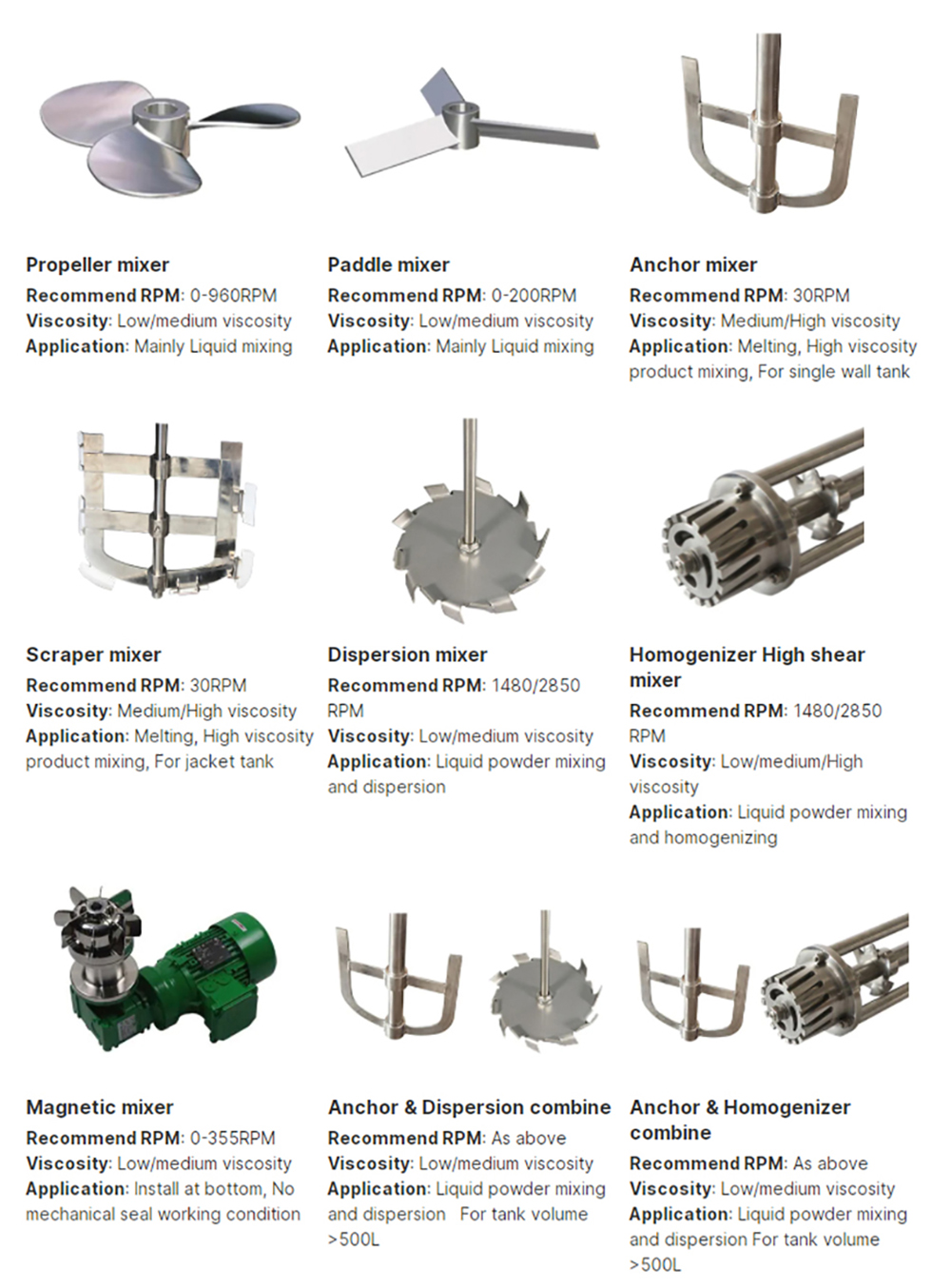

The agitator of the reaction tank is to promote the reactions of chemical substances. The choice of the agitator depends on the phase that needs to be mixed (one or several phases): Liquids only, liquid and solid. The agitators use in liquids can be placed on the top of the tank on vertical position, or horizontally (on the side of the tank) or less common, agitator is located on the bottom of the tank

Reaction vessel refers to any vessel used to contain the reactants taking part in a reaction. Our reaction vessel are make of 304 or 316L stainless steel. The reactor is usually have a heating or cooling Jacketed that can control the materials to keep within target temperature range. The reaction vessels are available in a variety of shapes and sizes to fit any volume required.

Please contact us with your specification of the tanks you want, Our engineering team will give you the best solutions!

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur