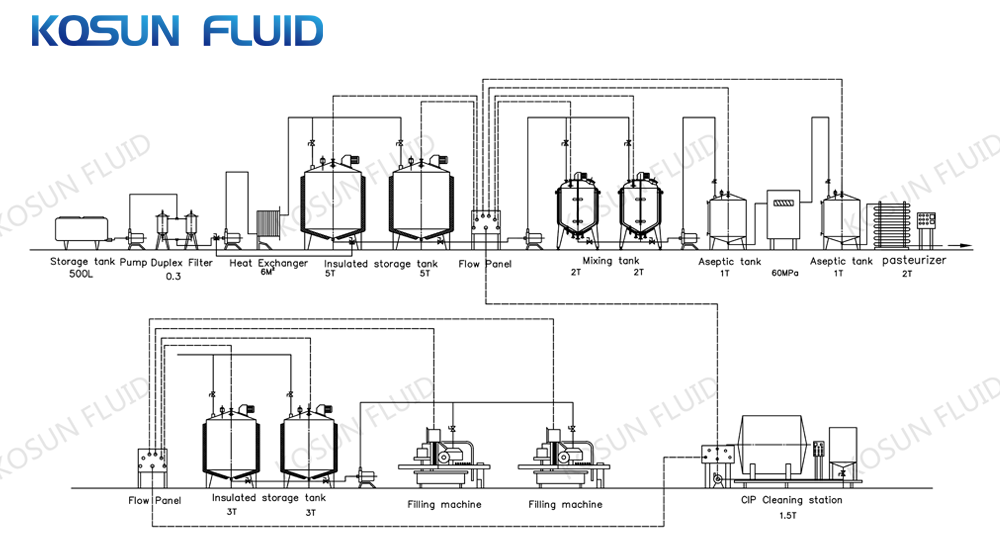

Stainless steel Diesel fuel biodiesel storage tank

As the drive for energy independence grows and biodiesel becomes more prevalent, the nation’s dependence on oil will be reduced. This massive movement toward biodiesel also has positive effects on the environment; namely, reduction in greenhouse gases and pollution. Biodiesel has many applications, from use in a standard diesel engine to a low carbon alternative to heating oil.

Our diesel fuel and biodiesel storage tank is all made of 304 stainlesss steel only, we do not fabricate carbon steel or plastic tanks.

The tank size from 500L up to 10000 liter,

the tank could also be used as a Sedimentation tank for biodiesel.

blending agitator is also available if customer need keep blending the product.

Please contact us with your specification of the tanks you want, Our engineering team will give you the best solutions!

|

Design Pressure:

|

-1 -10 Bar (g) or ATM

|

|||

|

Work Temperature:

|

0-200 °C

|

|||

|

Construction :

|

Vertical type or Horizontal type

|

|||

|

Jacket type :

|

Dimple jacket, full jacket, or coil jacket

|

|||

|

Structure :

|

Single layer vessel, vessel with jacket, vessel with jacket and insulation

|

|||

|

Heating or cooling function

|

According to the heating or cooling requirement ,the tank will have jacket for requried function

|

|||

|

Opitional Motor:

|

ABB, WEG, SEW or Chinese brand

|

|||

|

Surface Finish:

|

Mirror Polish or Matt polish or Acid wash&pickling or 2B

|

|||

|

Standard components :

|

Manhole,sight glass , cleaning ball

|

|||

|

Optional components :

|

Vent filter, Temp. Gauge, display on the gauge directly on the vessel Temp sensor PT100, digital display on the control cabinet by

instrument Temp sensor with control for heating and cooling Level gauge with digital display on the control cabinet by instrument Load cell Valves |

|||

|

Capacity (L)

|

100;300;500;1000;1500;2000;2500;3000;5000

|

|||

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur