stainless steel high speed high shear mixing tank

The tank is equipped with a high shear mixing agitator, It is capable of mixing one or more phase of another continuous phase efficiently, quickly and uniformly.

The high speed rotation of the rotor generate a stronger shearing force, to disperse the products.

1) The emulsification tank body adopts sanitary aseptic design;

2) It has online CIP cleaning and online SIP sterilization functions.

3) The structure design is humanized, simple to operate, convenient to maintain, and more hygienic without leaks.

4) Appropriate diameter-to-height ratio design, energy saving, fast material mixing, high emulsification and homogenization efficiency.

5) Smooth operation and low noise.

6) The surface of the inner tank is mirror-polished; the openings of the inlet and outlet pipes, sight glasses, manholes and the welding of the inner tank are all made of flanging arc transition, which is smooth and easy to clean without dead corners, ensuring the reliability of the production process Performance, stability, and compliance with GMP and other regulatory requirements.

7) It can be equipped with temperature display control and external level gauge

Please contact us with your specification of the tanks you want, Our engineering team will give you the best solutions!

|

Tank Data sheet

|

|

|

Tank Volume

|

From 50L upto 10000L

|

|

Material

|

304 or 316 Stainless steel

|

|

Insulation

|

Single layer or with insulation

|

|

Top Head type

|

Dish top, Open lid top, Flat top |

|

Bottom type

|

Dish bottom, Conical bottom, Flat bottom

|

|

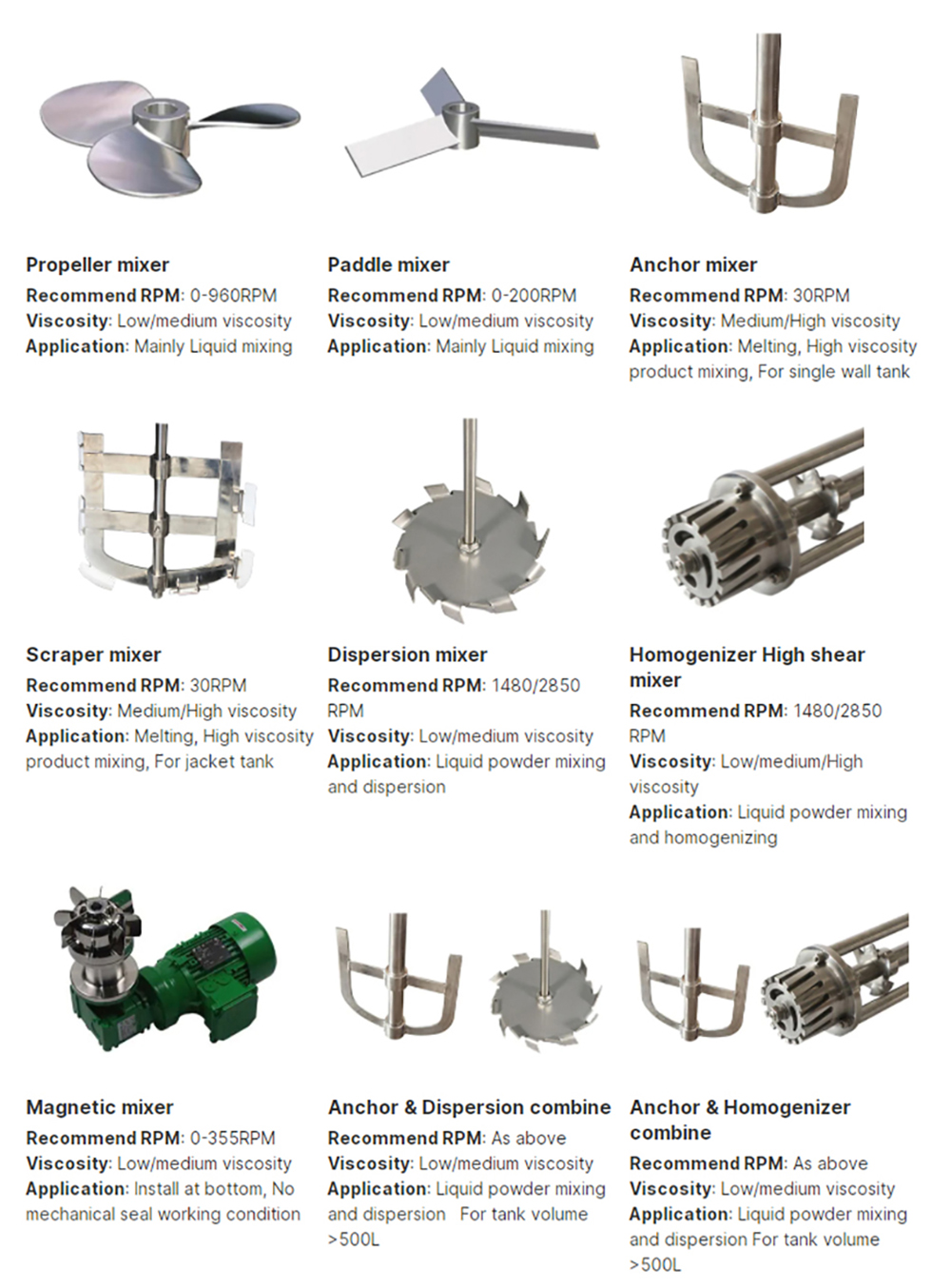

Agitator type

|

impeller, Anchor , Turbine , High shear, magnetic mixer, Anchor mixer with scraper

|

|

magnetic mixer, Anchor mixer with scraper

|

|

|

Inside Finsh

|

Mirror polished Ra<0.4um

|

|

Outside Finish

|

2B or Satin Finish

|

|

Application

|

Food, Beverage, pharmacy, biological

|

|

honey, chocolate, alcohol etc

|

|

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur