Stainless steel mixing tank with agitator

Mixing tank with an agitator is a versatile and efficient equipment that has become popular in many industries. It plays an essential role in mixing, blending and dispersing different materials such as powders, liquids, and gases. The mixing tank with agitator is a valuable tool that enhances production capacity, maintains product quality, reduces material wastage, and ensures high hygiene and safety standards.

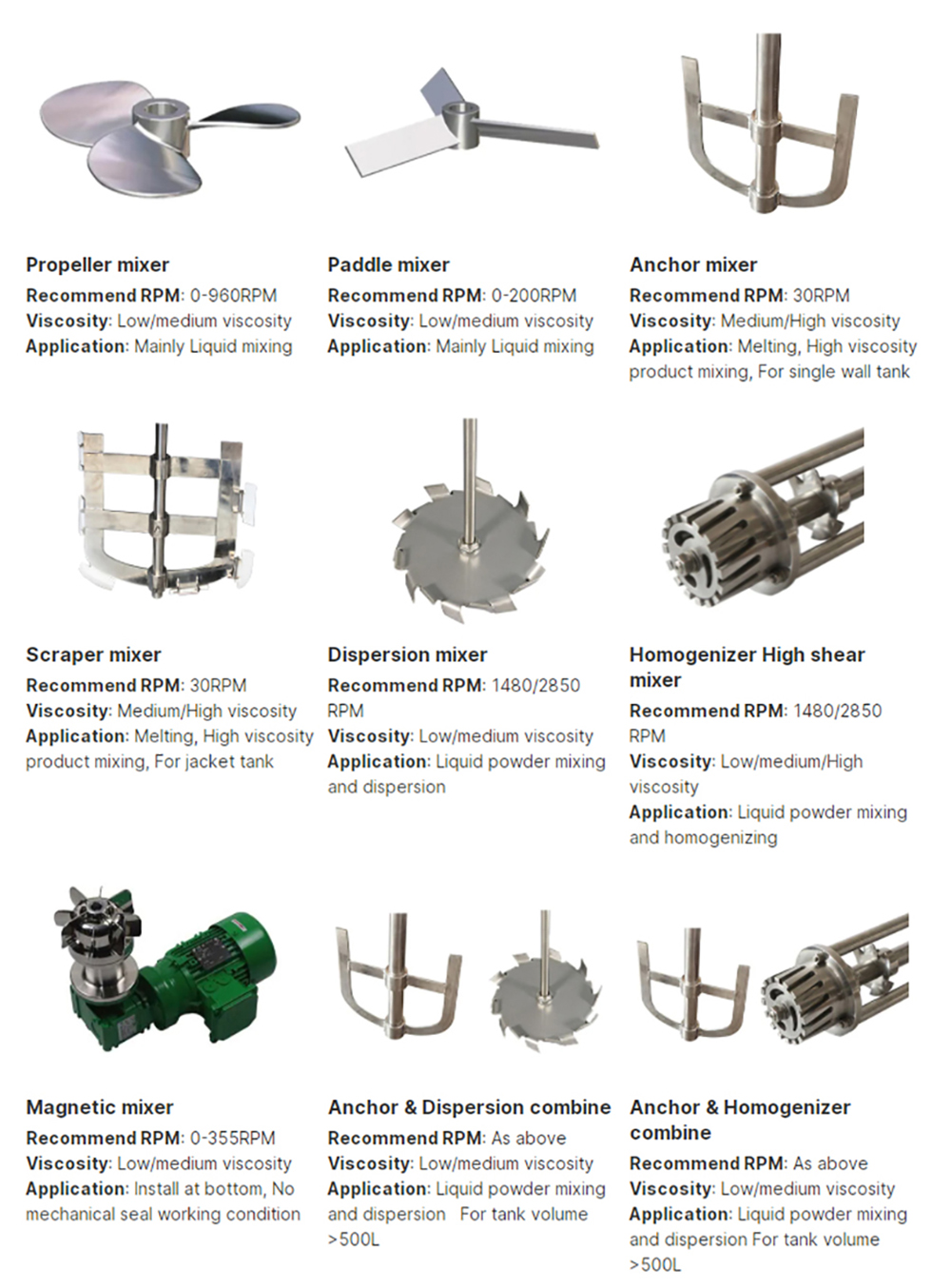

One of the significant benefits of the mixing tank with agitator is its ability to mix and blend different types of materials, regardless of their viscosity, density, or particle size. The agitator provides high shear force to break down large particles into smaller ones, which results in a uniform and homogeneous mix. This is particularly useful in the pharmaceutical, cosmetic, and food industries, where uniformity and consistency are paramount.

Another advantage of the mixing tank with agitator is that it improves the efficiency of the mixing process. The agitator efficiently mixes the materials in the tank, reducing the time and resources needed to achieve a desirable mix. This is particularly useful when working with expensive or time-sensitive materials, where speed and efficiency are critical.

The mixing tank with agitator is also easy to operate and maintain, making it a cost-effective investment for many industries. The agitator is designed to withstand harsh chemical environments and high temperatures, reducing the risk of breakdowns or equipment failures. Additionally, the tank's design allows for easy cleaning, reducing the risk of contamination and ensuring that high hygiene standards are maintained.

Moreover, the mixing tank with agitator is essential for maintaining high safety standards in various industries. It reduces the need for manual handling of hazardous materials, reducing the risk of workplace accidents. Additionally, it ensures that materials are mixed efficiently, reducing the risk of chemical reactions, spills, or explosions.

In conclusion, the mixing tank with agitator is a crucial piece of equipment that has revolutionized the manufacturing industry. It has become an essential tool that enhances production capacity, maintains product quality, reduces material wastage, and ensures high hygiene and safety standards. Its versatility, efficiency, ease of maintenance, and safety features have made it a valuable investment for industries that require consistent and uniform mixing and blending of materials.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur