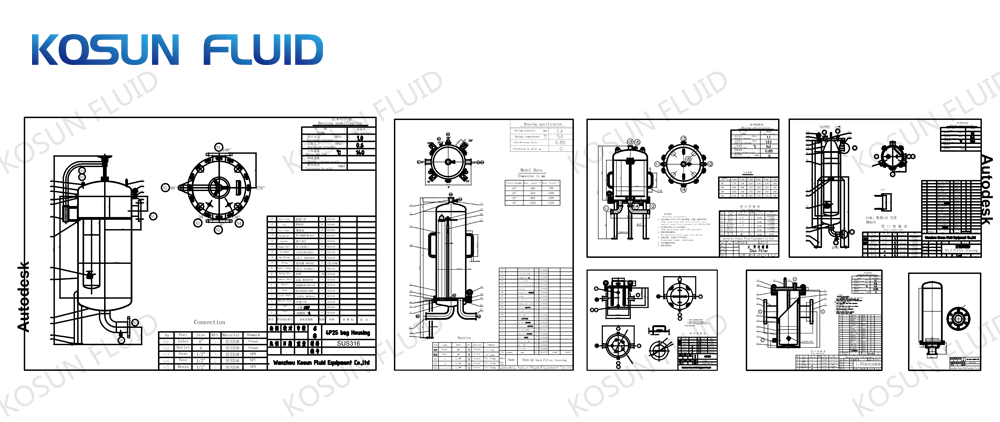

Stainless steel multi bag filter housing

These multi basket strainers and multi bag filter housings offer a wide range of flow capacities and contaminant-holding capabilities. They contain from 2 to 23 baskets.

To serve as a strainer, a unit is ordered with perforated stainless steel baskets (mesh-lined if desired). When ordered as a filter, it's fitted with perforated stainless steel baskets designed to hold disposable or cleanable filter bags. Industry-standard size bags are used: the standard 30 inch baskets accept bag size 2, the optional 15 inch baskets take size 1.

The standard pressure rating for all models is 150 psi. All multi basket strainer and multi bag filter housings can be supplied with an ASME code stamp, if required.

Inlet & Outlet of the multi bag filter housing could be customized, From 2" up to 8", Surface finish could be mirror polish, satin polish and sand blasting.

Features of the multi bag filter housings

Easy open by Swing bolts friendly operation with minimal downtime for bag change-outs. Reduces downtime to increase productivity and decrease operating costs.

Highest Capacity Available - up to 23 bags per vessel means higher flowrates and less downtime for bag changes .

Side inlet and bottom outlet provides easy and complete drainage. A tangential outlet option is available to reduce the height of the housing making filter bag change-out easier.

Application of the multi bag filter housings

1. Pre-treatment for various kind of water

2. Used in RO system ,EDI system and UF system,etc.

3.Used for paint, beer, vegetable oil, pharmaceuticals, chemicals, petroleum products, textile chemicals, photographic chemicals, electroplating liquid, milk, mineral water, thermal solvents, emulsions, industrial water, syrup, resin, printing ink, industrial waste water, fruit juice, edible oil, wax, etc.

|

Module Dimension |

Total height (mm) |

Shell height(mm) |

Diameter (mm) |

Inlet/outlet mm) |

N.W (kg) |

| 2P1S | 1510 | 590 | 400X3 | DN50 | 63 |

| 3P1S | 1550 | 610 | 450X3 | DN65 | 96 |

| 4P1S | 1600 | 630 | 500X3 | DN80 | 114 |

| 5P1S | 1630 | 630 | 550X3 | DN80 | 139 |

| 6P1S | 1750 | 660 | 650X4 | DN100 | 200 |

| 7P1S | 1750 | 660 | 650X4 | DN100 | 200 |

| 8P1S | 1830 | 680 | 700X4 | DN125 | 230 |

| 9P1S | 1990 | 710 | 750X4 | DN150 | 261 |

| 11P1S | 2205 | 780 | 800X5 | DN200 | 307 |

| 12P1S | 2230 | 780 | 850X5 | DN200 | 378 |

| 2P2S | 1830 | 910 | 400X3 | DN50 | 93 |

| 3P2S | 1870 | 930 | 450X3 | DN65 | 108 |

| 4P2S | 1920 | 950 | 500X3 | DN80 | 127 |

| 5P2S | 1950 | 950 | 550X3 | DN80 | 152 |

| 6P2S | 2070 | 980 | 650X4 | DN100 | 221 |

| 7P2S | 2075 | 980 | 650X4 | DN100 | 225 |

| 8P2S | 2150 | 1000 | 700X4 | DN125 | 253 |

| 9P2S | 2310 | 1030 | 750X4 | DN150 | 285 |

| 11P2S | 2525 | 1100 | 800X5 | DN200 | 339 |

| 12P2S | 2550 | 1100 | 850X5 | DN200 | 413 |

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur