Umgangatho we-welding we-welding seam ye-stainless steel pressure tank yamanzi ichaphazela ngokuthe ngqo ukhuseleko lomkhumbi woxinzelelo.Kukho iindlela ezininzi ze-welding, i-argon arc welding yenye yeendlela ezifanelekileyo ze-welding, kodwa xa ububanzi bukhulu kune-800mm kwaye umthamo ukhulu kakhulu, ukukhuselwa kokuzaliswa kwe-argon yangaphakathi kuzisa ubunzima obuthile kwaye kwandisa iindleko zokuvelisa.Inkqubo ye-arc-arc arc welding ephindwe kabini isetyenziselwa ukuwelda komthungo we-circumferential kunye ne-longitudinal seam yesikhongozeli, ephucula kakhulu umgangatho we-welding kunye nokusebenza kakuhle kwe-welding kunye nokunciphisa iindleko zemveliso.

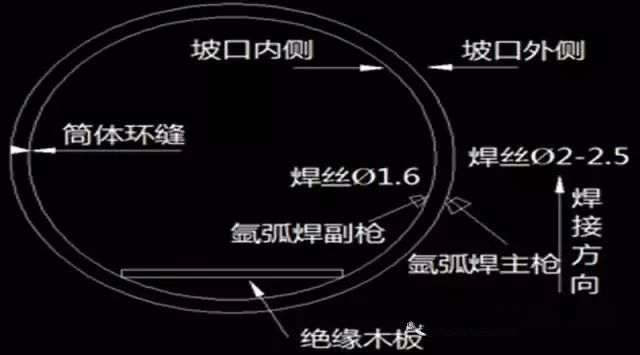

Umgqomo wamkela inkqubo ye-welding ephindwe kabini ye-arc ye-argon arc welding, kwaye i-workpiece yenziwe ibe yi-V-shaped groove.Kwindawo ethe nkqo, ii-welders ezimbini kunye nemithombo emibini yamandla ezimeleyo isetyenziselwa ukudibanisa amacala angaphakathi nangaphandle kwendawo yokusebenza kunye ne-pool etyhidiweyo.ukuwelda.Emva kwe-welding ephantsi, ukuzaliswa kunye nokugubungela i-welding kugqitywe nge-arc enye.Ukuphelisa inkqubo yangaphambili yokuzalisa i-argon kwicala elingasemva kunye nokunciphisa inkqubo yokucoca ingcambu kwicala elingasemva;ine-weldability elungileyo kwaye inokulawula ngokufanelekileyo ukuphakama kwe-weld yecala elingasemva;ngenxa yokuba i-arc ephindwe kabini ikwandisa amandla okuvuselela i-pool etyhidiweyo kunye ne-fluidity ye-pool etyhidiweyo, ingenza i-pool etyhidiweyo ngokupheleleyo i-Fusion inciphisa iziphene ezifana ne-slag inclusions, ii-pores, kunye nokungena okungaphelelanga;ineempawu zegalelo elincinci lobushushu, i-welding deformation encinci, ukunciphisa uxinzelelo oludibeneyo, kunye nokunyuka kakhulu ukungena.

Iimfuno zeNdibano

1.1 Sebenzisa iqonga elikhethekileyo ngexesha lokudibanisa ukuze lihlukanise kwezinye izinto zetsimbi ezifana nentsimbi yekhabhoni;kuphephe imikrwelo ebangelwa kukungqubana ngexesha lokuhamba;izilingi ezikhethekileyo kunye nezixhobo, ezifana neebhanti zenylon, kufuneka zisetyenziselwe ukuphakamisa, kwaye iintambo zensimbi zensimbi zithintelwe ngokungqongqo ukuphepha ukukrwela umphezulu wesinyithi.

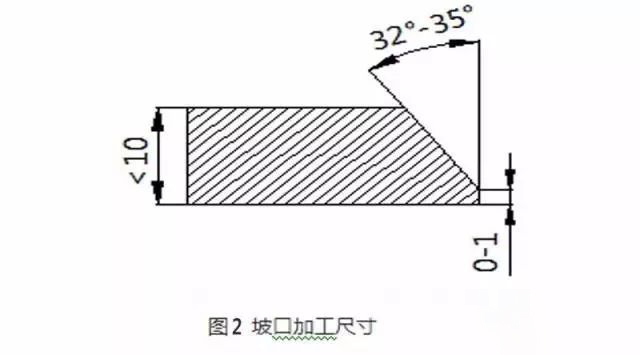

1.2 Khetha amacwecwe afanelekileyo ngokuhambelana ngokuthe ngqo neemfuno zoyilo lwemizobo, misela ubungakanani bokwenene bezinto eziphathekayo, sebenzisa i-plasma cutting okanye i-machining ukusika izinto eziphathekayo, kwaye i-grooves kufuneka ilungiswe ngomatshini okanye iindlela zokugaya.Ukucutshungulwa, intloko ihlanjululwe yi-grinder, kwaye imilinganiselo ethile iboniswe kuMfanekiso 2.

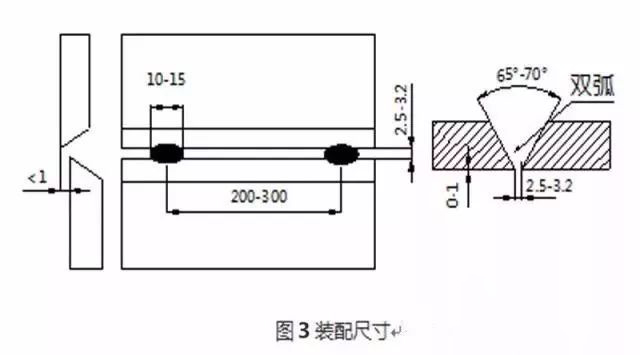

Emva kokugqitywa kokulungiswa, ukuqengqeleka kweentambo ezintathu kusetyenziselwa ukusetyenzwa kwe-arc.Ubungakanani bendibano buboniswe kuMzobo 3. Coca i-10 ~ 15mm kumacala omabini e-groove, i-gap yendibano yi-2.5 ~ 3.2mm, i-offset yeplate ingaphantsi kwe-10% yobunzima bodonga, kwaye ingabi ngaphezu kwe-1mm. , usebenzisa i-argon arc welding, ubude 10 ~15mm, ubukhulu 3~4mm.Ukuqaliswa kwe-arc kunye nokupheliswa kwe-arc kufuneka kuqhutywe ebusweni be-groove.Emva kokudibanisa, sebenzisa i-polisher ukupolisha umphambili kunye nomva we-solder joints ukuze ubone ukukhazimula.

1.3 Ngexesha lokudibanisa, gwema ukudibanisa ngokunyanzeliswa ukunciphisa uxinzelelo lwangaphakathi lwamacandelo.Zama ukuphepha ezinye izinto ezingcolisa okanye ukukrwela umphezulu webhodi.

Akuvunyelwe ukubetha ii-arcs ngokungenamkhethe okanye u-weld ngokungenamkhethe kwaye ufake amacandelo ethutyana kumphezulu we-cylinder.Imiphezulu kumacala omabini e-weld kufuneka igweme ukusebenzisa isando ukuyilungisa.

Inkqubo yokuwelda

2.1 Amalungiselelo phambi kokuba welding

Coca i-rust layer, umswakama, ioli, uthuli, njl. 10-15mm kumacala omabini e-groove.

2.2 Ukukhethwa kwezinto ezisetyenziswa ngokuqhelekileyo zokuwelda (jonga kwiThebhile 1)

| Isiseko sesinyithi | Ucingo lokuwelda |

| I-SUS 304 | I-ER 308 |

| SUS 304L | ER 308L |

| SUS 316 | ER 316 |

| SUS 316L | ER 316L |

| SUS 321 | ER 321 |

Iiparamitha zeWelding (jonga kwiTheyibhile 2)

| Ubukhulu bentsimbi esisiseko (mm) | Idayamitha yocingo (mm) | Umphezulu we-welding | Uhlobo lwangoku kunye ne-polarity | Welding current (A) | Ukuhamba kwerhasi (L/min) |

| 4-10 | Φ1.6 | Non-groove | Uxhulumaniso oluhle lwe-DC | 20~50 | 6~10 |

| Φ2~2.5 | Bevel ubuso | Uxhulumaniso oluhle lwe-DC | 70-110 | 8~10 |

2.3 Amanyathelo okuthintela ukuwelda

Khetha izixhobo zokuwelda ezifanelekileyo ngokwepleyiti, sebenzisa Φ1.6mm ucingo welding ngaphakathi weld, welding yangoku 20~50A, ngaphandle khetha Φ2 ~ 2.5mm ucingo welding ngokobukhulu bepleyiti, welding yangoku 70~110A, kwaye usebenzise welding ephantsi yangoku fast for bottoming.Ukuzalisa kunye ne-capping layers kufuneka zikhethe iindlela ze-welding ezifana ne-argon arc welding, i-electrode arc welding, kunye ne-CO2 yegesi ekhuselekileyo ye-welding ngokwemiqathango ethile.Xa ubukhulu bepleyiti bungaphantsi kwe-10mm, zama ukungasebenzisi i-arc entywilayo ye-welding.

2.4 Ukuhlolwa kwe-welding

Emva kweeyure ze-48 ze-welding, ifilimu kunye novavanyo olungonakaliyo lwe-welding seam lwenziwa.Le nkqubo ithatha i-double-arc argon arc welding for bottoming, i-argon arc welding yokugcwalisa umphezulu we-cover, i-welding seam filming kunye novavanyo olungonakalisi lombala lufanelekile, kwaye uvavanyo lokugoba, uvavanyo lwamandla okuqina kunye novavanyo lwe-corrosion ye-intergranular zonke ziyahlangabezana. izalathisi ezikhankanyiweyo.

2.5 Unyango lwasemva kweweld

Emva kovavanyo olungonakalisi kunye novavanyo lwamandla, ukuchongwa kunye nokunyangwa kwe-passivation kwenziwa kwi-weld kunye nommandla okufutshane womthungo.

Inkqubo ephantsi ye-double-arc arc arc welding yensimbi engenasici yenye yeendlela ezifanelekileyo ze-welding.Njengokusebenza okuphezulu, ukonga amandla, umgangatho ophezulu kunye nenkqubo ye-welding yezoqoqosho, i-double-arc welding inemibono emihle yesicelo kwimveliso yangempela.

Ixesha lokuposa: Jun-13-2022