Ikhwalithi ye-welding ye-welding seam ye-stainless steel pressure tank water tank ithinta ngokuqondile ukuphepha komkhumbi wokucindezela.Kunezindlela eziningi ze-welding, i-argon arc welding ingenye yezindlela ezikahle zokuthungatha, kodwa lapho ububanzi bukhulu kuno-800mm futhi ivolumu inkulu kakhulu, ukuvikelwa kokugcwalisa i-argon yangaphakathi kuletha ubunzima obuthile futhi kwandisa izindleko zokukhiqiza.Inqubo ye-double-arc arc arc welding isetshenziselwa ikakhulukazi ukushisela umthungo ojikelezayo kanye nomthungo we-longitudinal wesitsha, okuthuthukisa kakhulu izinga lokushisela nokusebenza kahle kwe-welding futhi kunciphisa izindleko zokukhiqiza.

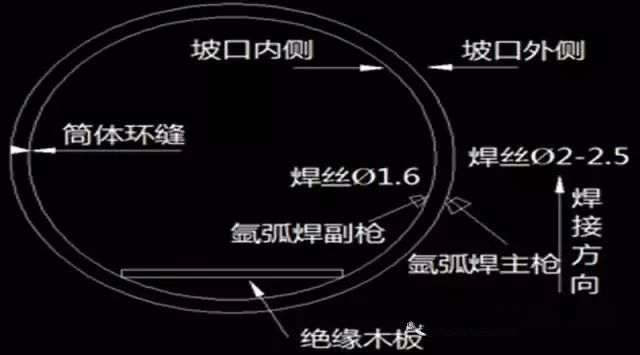

Umgqomo wamukela inqubo yokushisela ezinhlangothini ezimbili ye-arc ye-argon arc welding, futhi ucezu lokusebenza lwenziwa umsele omise okwe-V ohlangothini olulodwa.Esimeni esiqondile, ama-welders amabili kanye nemithombo emibili yamandla azimele asetshenziselwa ukuxhuma izinhlangothi zangaphakathi nezangaphandle ze-workpiece nedamu elincibilikisiwe.ukushisela.Ngemuva kwe-welding engezansi, ukugcwaliswa kanye ne-cover welding kuqedwa nge-arc eyodwa.Iqeda inqubo yangaphambilini yokugcwalisa i-argon ohlangothini olungemuva futhi inciphisa inqubo yokuhlanza impande ohlangothini olungemuva;inokushisela okuhle futhi ingakwazi ukulawula ngempumelelo ukuphakama kwe-weld side reverse;ngenxa yokuthi i-arc ephindwe kabili ikhulisa ikhono elishukumisayo lechibi elincibilikisiwe kanye nokumanzi kwechibi elincibilikisiwe, ingenza ichibi elincibilikisiwe ngokugcwele I-Fusion inciphisa amaphutha afana nokufakwa kwe-slag, ama-pores, nokungena okungaphelele;inezici zokufaka ukushisa okuncane, i-welding deformation encane, ukunciphisa ukucindezeleka kwamalunga, nokwanda kokungena okwandayo.

Izidingo zomhlangano

1.1 Sebenzisa isiteji esikhethekile ngesikhathi sokuhlanganisa ukuze uyihlukanise kwezinye izinto zensimbi njenge-carbon steel;gwema imihuzuko ebangelwa ukushayisana ngesikhathi sokuthutha;izihlilingi ezikhethekile kanye nezakhiwo, njengamabhande enayiloni, kufanele kusetshenziselwe ukuphakamisa, futhi izintambo zensimbi zensimbi zivinjelwe ngokuqinile ukugwema ukunwaya indawo yensimbi.

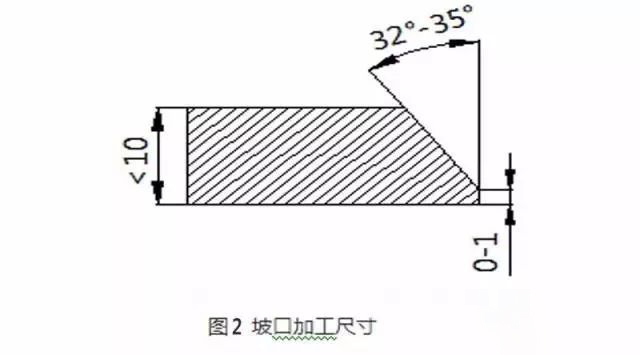

I-1.2 Khetha amapuleti afanelekayo ngokuhambisana ngokuqinile nezidingo zokuklama imidwebo, thola ubukhulu bangempela bento ngayinye, sebenzisa ukusika kwe-plasma noma umshini wokusika izinto, futhi ama-grooves kufanele alungiswe ngomshini noma izindlela zokugaya.Ukuze kucutshungulwe, ikhanda liboshwe nge-grinder, futhi ubukhulu obuthile buboniswa kuMfanekiso 2.

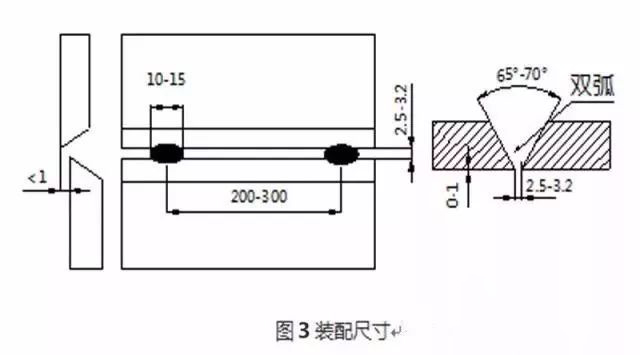

Ngemuva kokuthi ukucubungula sekuqediwe, ukugoqa kwezintambo ezintathu kusetshenziselwa ukucubungula i-arc.Usayizi womhlangano uboniswa kuMfanekiso 3. Hlanza i-10 ~ 15mm ezinhlangothini zombili ze-groove, igebe lomhlangano liyi-2.5 ~ 3.2mm, i-offset yepuleti ingaphansi kuka-10% wobukhulu bodonga, futhi hhayi ngaphezu kuka-1mm. , usebenzisa i-argon arc welding, ubude 10 ~15mm, ukujiya 3~4mm.Ukuqaliswa kwe-arc kanye nokuqedwa kwe-arc kufanele kwenziwe ebusweni be-groove.Ngemva kokuhlanganisa, sebenzisa i-polisher ukupholisha ingaphambili nangemuva lamalunga e-solder ukuze ubone ukucwebezela.

1.3 Ngesikhathi sokuhlanganisa, gwema ukuhlanganisa ngempoqo ukuze unciphise ukucindezelwa kwangaphakathi kwezingxenye.Zama ukugwema ezinye izinto ezingcolisa noma ukunwaya ingaphezulu lebhodi.

Akuvunyelwe ukushaya ama-arcs noma ukushisela ngokungahleliwe futhi ufake izingxenye zesikhashana endaweni yesilinda.Indawo ezinhlangothini zombili ze-weld kufanele igweme ukusebenzisa isando ukuyilungisa.

Inqubo yokushisela

2.1 Ukulungiselela ngaphambi kokushisela

Hlanza ungqimba lokugqwala, umswakama, amafutha, uthuli, njll. 10-15mm ezinhlangothini zombili ze-groove.

2.2 Ukukhethwa kwezinto ezisetshenziswa kakhulu zokushisela (bheka Ithebula 1)

| Isisekelo sensimbi | Intambo yokushisela |

| I-SUS 304 | ER308 |

| I-SUS 304L | ER 308L |

| I-SUS 316 | ER316 |

| I-SUS 316L | ER 316L |

| I-SUS 321 | ER321 |

Imingcele yokushisela (bheka Ithebula 2)

| Ukujiya kwesisekelo sensimbi (mm) | Ububanzi bentambo (mm) | Welding surface | Uhlobo lwamanje kanye ne-polarity | I-Welding current (A) | Ukugeleza kwegesi (L/min) |

| 4-10 | Φ1.6 | I-Non-groove | Ukuxhumana okuhle kwe-DC | 20~50 | 6~10 |

| Φ2~2.5 | Ubuso bevel | Ukuxhumana okuhle kwe-DC | 70~110 | 8~10 |

2.3 Izinyathelo zokuphepha zokushisela

Khetha impahla yokushisela efanele ngokusho kwepuleti, sebenzisa i-Φ1.6mm welding wire ngaphakathi kwe-weld, i-welding yamanje engu-20~50A, ngaphandle khetha i-Φ2 ~ 2.5mm intambo yokushisela ngokusho kobukhulu bepuleti, i-welding yamanje engu-70~110A, futhi usebenzise welding low yamanje fast for bottoming.Izendlalelo zokugcwalisa kanye ne-capping kufanele zikhethe izindlela zokushisela ezifana ne-argon arc welding, i-electrode arc welding, kanye ne-CO2 yegesi evikelekile yokushisela ngokuvumelana nezimo ezithile.Uma ubukhulu bepuleti bungaphansi kuka-10mm, zama ukungasebenzisi ukushisela okuzenzakalelayo kwe-arc.

2.4 Ukuhlolwa kokushisela

Ngemuva kwamahora angu-48 wokushisela, ukuhlolwa kwefilimu nombala okungabhubhisi kwe-welding seam kwenziwa.Le nqubo ithatha i-double-arc argon arc welding for bottoming, i-argon arc welding yokugcwalisa ikhava, ukuthwebula i-seam ye-welding kanye nokuhlolwa okungabhubhisi kombala konke kuyafaneleka, futhi ukuhlolwa kokugoba, ukuhlolwa kwamandla okuqinile kanye nokuhlolwa kokugqwala kwe-intergranular konke kuhlangabezana izinkomba ezishiwo.

2.5 Ukwelashwa kwe-post-weld

Ngemuva kokuhlolwa okungonakalisi nokuhlolwa kwamandla, ukwelashwa kwe-pickling kanye ne-passivation kwenziwa kwi-weld kanye nendawo eseduze yomthungo.

Inqubo yokubeka phansi ye-double-arc arc arc welding yensimbi engagqwali ingenye yezindlela ezikahle zokushisela.Njengokusebenza kahle kakhulu, ukonga amandla, inqubo yokushisela yekhwalithi ephezulu kanye neyomnotho, i-double-arc welding inamathuba amahle okufaka isicelo ekukhiqizeni kwangempela.

Isikhathi sokuthumela: Jun-13-2022